News

What is LCD screen repair COF ACF bonding?

ACF machine

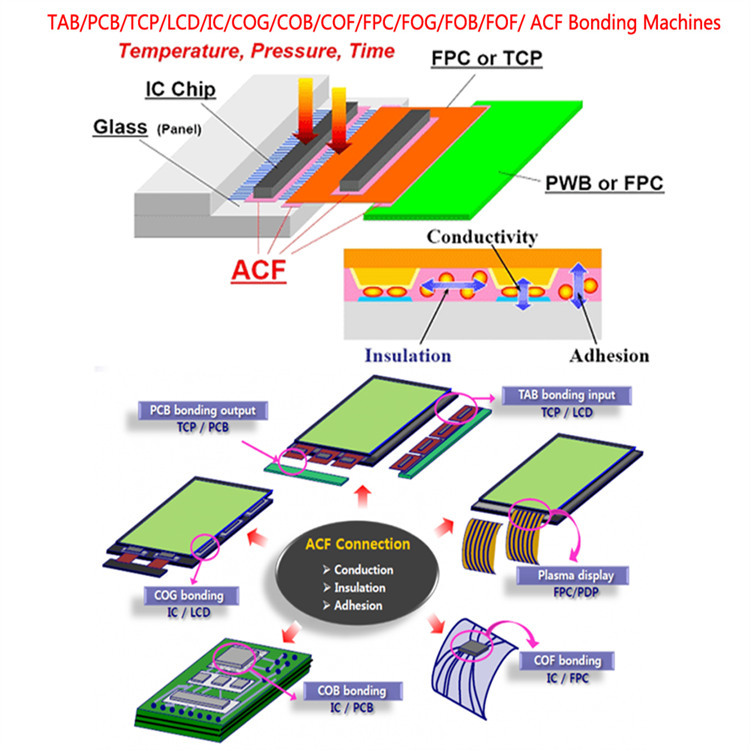

ACF machine ,it may press the IC/FPC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time. also some machine use the Solder paste as the medium.

bonding machine

It has pulse heat bonding machine and constant temperature bonding machine.

The machine may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process.

The Machine is based on the recent innovations as well as planned to repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.It is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display produce factories and repairing service shops all over the world.

What is ACF bonding?

During ACF bonding, a combination of heat & pressure is applied on to chip (FPC/IC) for an appropriate time.

Conductive particles (each 3~30um) are compressed between IC and substrate (glass / PCB) while insulating materials pushed away.

This allows the compressed Ni-Au layer on the particles to conduct electricity between the IC and the substrates (z-axis).

The insulated particles are distributed with a minimum chance of electrical shorting in the x-axis and y-axis.

As the epoxy cures and conductive particles are trapped into permanent compressed form.

The compressed particles, by its elastic nature, are constantly pushing outwards to maintain good electrical conductivity under different environmental conditions.

ACF machine Applications

ACF machine has for many years, been used in glass display applications. Recently, it is also becoming widely used in TAB,COG,FOG,FOB,FOF,COF,COB areas.

– TAB Bonding (TCP-PCB / TCP-LCD)

– COG Bonding (IC-LCD)

– COB Bonding (IC-PCB)

– COF Bonding (COF-LCD/PCB)

– FOG Bonding(FPC-LCD)

– FOB Bonding(FPC-PCB)

– FOF Bonding(FPC-FPC)

– Plasma Display (FPC-PDP)

– Flip Chip Package

– ……

Features

Heat cure

Fast bonding time

High adhesion to plastic PET,COF & FPC, substrate

Excellent thermal stability

Good contact resistance for reliability

Good corrosion resistance

Excellent chemical resistance

Good for wide bonding temperature range

Replaces solder for lead-free solution

Because of many advantages and features ,the machine is becoming more and more popular and useful.

Categories

Contact Us

- +8613172493285

- +86-75533940745

- +8613172493285

- sales@cofbondingmachine.com

- instrument.world

- 8613172493285

售前客服

售前客服